Ultrasonic Testing

Ultrasonic inspection (UT) is a non-destructive testing method that uses high frequency sound energy to conduct examinations on ferrous and non-ferrous materials. Ultrasonic inspection (UT) can be used for flaw detection and evaluation, dimensional measurements, material characterization and more. Ultrasonic inspection (UT) is a very useful and versatile NDT method. Some of the advantages of ultrasonic inspection that are often cited include:

- It is sensitive to both surface and subsurface discontinuities

- The depth of penetration for flaw detection is superior to other NDT methods

- Only single sided access is needed when the pulse-echo technique is used

- It is highly accurate in determining the size and shape of a defect

- Minimal part preparation is required

- Electronic equipment provides instantaneous results

- It has other uses, such as thickness measurements, in addition to flaw detection

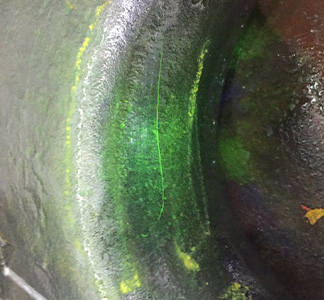

Cracks found in crane hook with blacklight inspection

Magnetic Particle Testing

Magnetic particle inspection (MPI), is a non-destructive test method for the detection of surface and sub-surface discontinuities in ferrous materials. The test method involves application of magnetic field externally or applying electric current through the material which in turn produces magnetic flux in the material. Simultaneously, visible ferrous particles are sprinkled or sprayed on the test surface.

The presence of a surface or near surface discontinuities in the material causes distortion in the magnetic flux which in turn causes leakage of the magnetic fields at the discontinuity. The magnetic particles are attracted by the surface field in the area of the discontinuity and adhere to the edges of the discontinuity appearing the shape of the discontinuity particle inspection uses an externally applied AC or DC current field of magnetism to detect surface or near surface defects in steel plate, castings, forgings, high stress weld areas, etc.

The presence of a surface or near surface discontinuities in the material causes distortion in the magnetic flux which in turn causes leakage of the magnetic fields at the discontinuity. The magnetic particles are attracted by the surface field in the area of the discontinuity and adhere to the edges of the discontinuity appearing the shape of the discontinuity particle inspection uses an externally applied AC or DC current field of magnetism to detect surface or near surface defects in steel plate, castings, forgings, high stress weld areas, etc.

There are different types of magnetic particle inspection:

- Visible method, either wet or dry magnetic particles

- Fluorescent method, either wet or dry magnetic particles

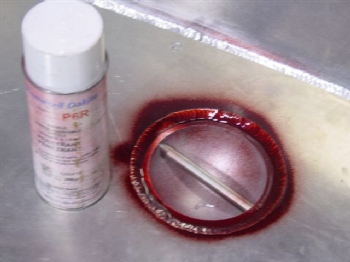

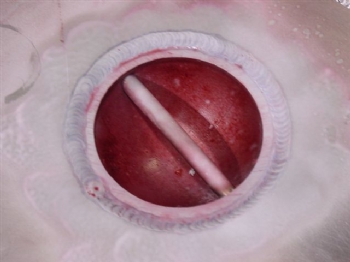

Dye Penetrant Testing

Dye penetrant inspection (DPI), also called liquid penetrant inspection (LPI), is widely applied and low-cost inspection method used to locate surface-breaking defects in all non-porous materials. Dye pentrant is used mostly for detecting defects in castings and forgings, leaks in new products, and fatigue cracks on in-service components. Liquid Penetrant Testing involves the coating of a test object with a visible dye solution. The dye then sits for the necessary time needed for the process to work and to reveal the imperfections found in the surfaces of the test object. This works by removing the excess dye from the object and apply a developer which then draws out the remaining dye out of any surface imperfections revealing any flaws in the test object.

There are two types of dye penetrant test:

- Visible red dye penetrant inspection

- Fluorescent dye pentrant inspection

Load Testing

Our portable load testing equipment is used for testing pad eyes on basket, boxes, skids, oilfield equipment, etc. During testing, we conduct a visual inspection and an inspection of all material welds in critical load stress areas. A Magnetic Particle Inspection (MPI) or a Dye Penetrant Inspection (DPI) of all critical areas is performed after a load test to check for fractures or cracks. We provide a certificate of load test and inspection along with NDT documentation plus a stainless steel nameplate to be attached to all equipment inspected.

QCS Inspection Services

At QCS we provide professional and quality precision in-house and on-site inspections services. Our inspection services are performed by our expert personnel that have been trained and qualified to the latest standards of SNT-TC-1A and have achieved Level II qualifications for Ultrasonics, Magnetic Particle, Dye Penetrant, and Visual inspection. We also perform video borescope inspections for drill motors and drill collars and pipe.

We provide NDE inspection for equipment and parts included in the following:

- BHA

- Connections

- Handling Tools

- Hoisting Equipment

- Welds

- Pipe

- Drill Motors

- Pad Eyes

Ultra Hostile Environment Tags

Our highly versatile, extremely resistant and industry-thick stainless steel tags are capable of reliably and consistently withstanding the harshest of the elements associated with metal manufacturing. We use a StyleWrite computer, the best in its class, operating with a driven electric over-air-powered engraver that makes reading our tags convenient, effortless and innovatively genius.

24/7 Customer Online Data Base

Our online database can be accessed by our customers 24/7 to view and print all certifications.

Our certificate tracking software consists of:

- Catalogs and track your inventory

- Provides easy access to your certificates

- Web-based which means you can access your certificates from any computer

- Reduces your downtime

- Reduces your overhead

- Increase productivity

- Increases profits

- Provides you with a cost effective certificate management system